A função executa existe para que além de troca de dados nas integrações, sejam executadas funções que exijam procedimentos, telas ou aplicações que tenham grau de complexidade conhecida. Fazendo a validação, tratamento, transformação ou cálculos.

Permite a criação de rotinas prévias ou posteriores de crítica e validação, além da possibilidade de desenvolvimento de aplicações que complementem rotinas.

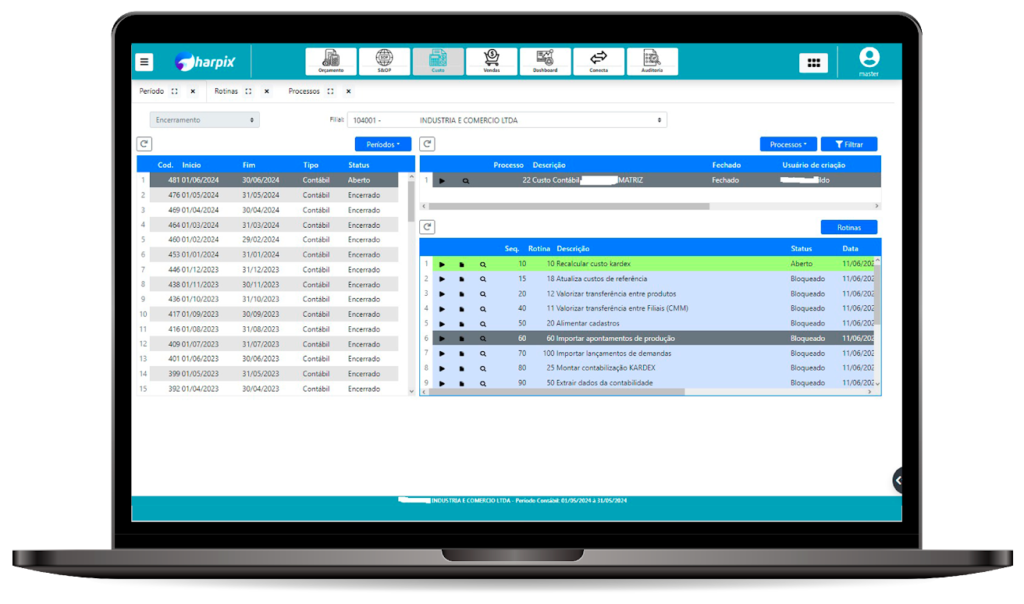

Acompanhar, gerenciar e controlar todos os períodos de execução, processos e rotinas executadas pela empresa/filial.

– Visão dos processos por usuário

– Tipo de usuário: executor ou interessado

– Análise dos logs de erro e avisos

– Reprocessamento manual e automático de erros

– Consultas de dados resultantes do processamento

– Controle do fechamento de períodos e encerramento dos processos

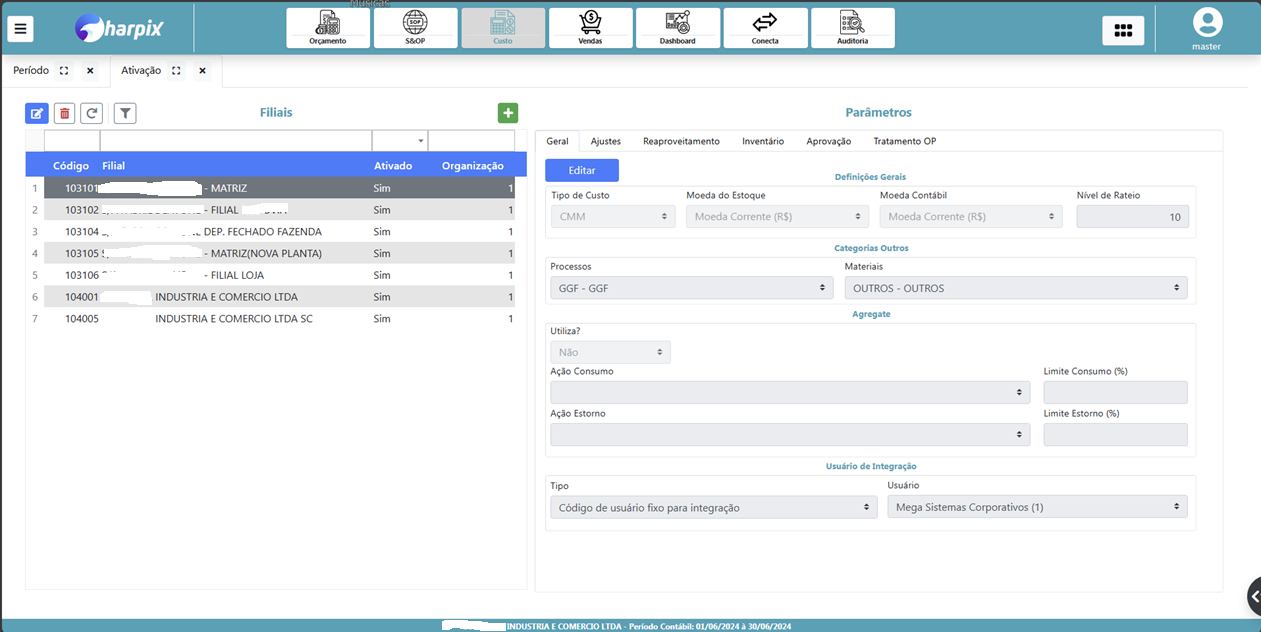

A plataforma possui uma variedade extensa de configurações com o objetivo de atender diversas aplicações e permite o desenvolvimento e configuração de processos e rotinas estruturadas.

– Agenda de execução dos processos

– Configuração de usuários

– Configuração de filiais

– Contabilização

– Critérios de Rateio

– Taxas de Custo

– Tipos de LOG

– Tipos de Alerta

– Tratamento de erros

– Regras e ações

– Formulários

– Triggers e procedimentos

– Matriz de risco

Os dados mestres são cadastros essenciais para a execução correta de

parâmetros padrões e auxiliares, para o sucesso das rotinas, sem este dados a execução é possível.

– Filiais

– Contas contábeis

– Produtos

– Contabilização

– Clientes, fornecedores e representantes

– Centros de custo

– Centros de trabalho

– Custos de referência

– *É possível adicionar informações personalizadas aos cadastros existentes

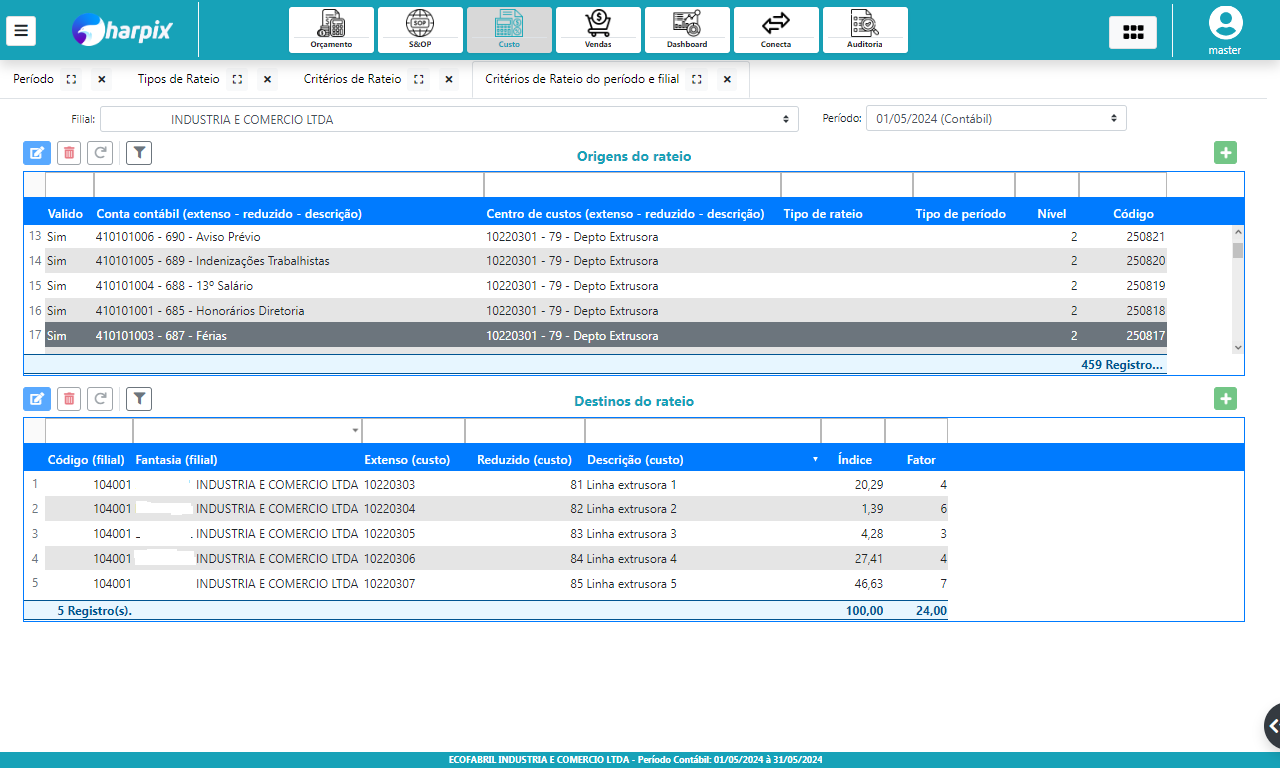

Configuração e definição de tipos de rateio com critérios dinâmicos, além das origens e destinos de tipos de rastreios parametrizáveis e cálculo e apresentação dos índices de rateio apurados.

– Percentual

– Quantidade produzida

– Tempo padrão e de produção

– Customizado

– Percentual

– Por fator

– Por período

– Por filial

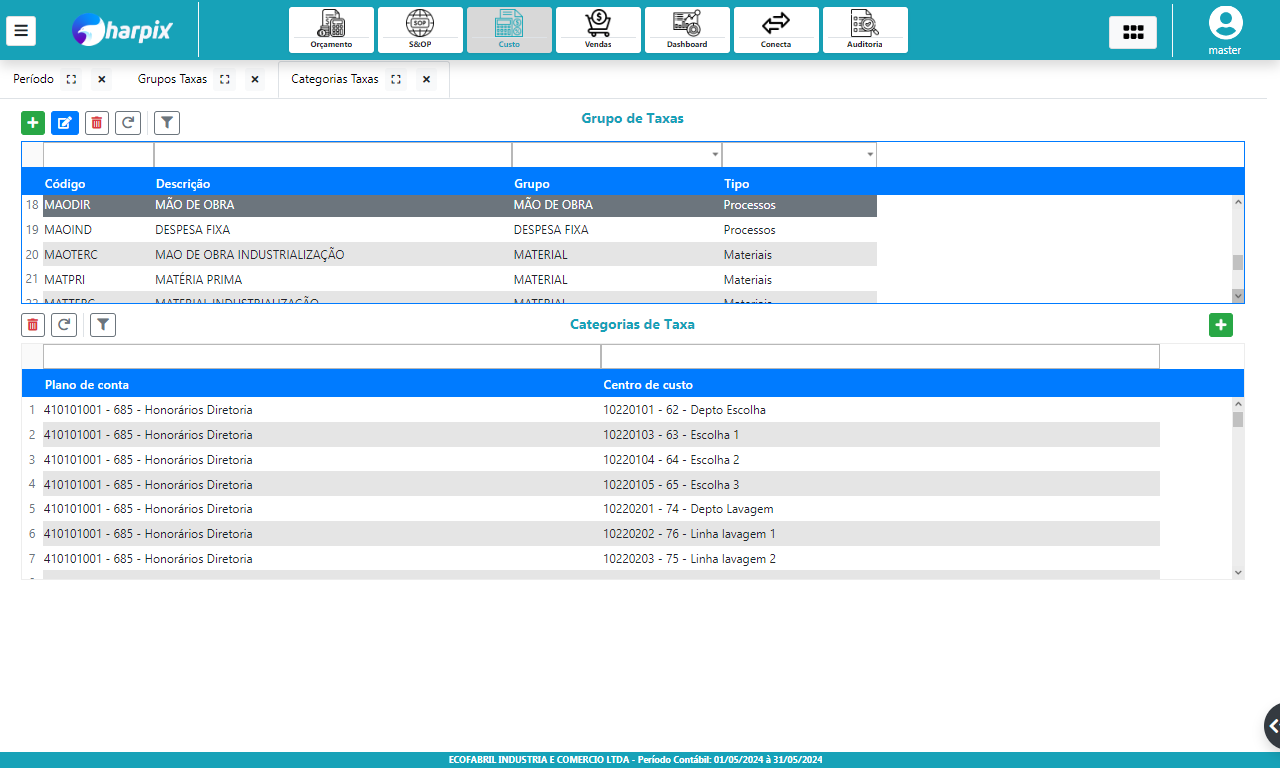

Grupos de taxas ilimitadas e criação do vínculo (origem/destino) entre as taxas e grupos de processos e materiais com plano de contas e centro de custos.

– Mão de obra direta e indireta, entre outros

– Materiais aplicados (embalagens, insumos, outros)

– Por relação direta com contas sintéticas ou analíticas

– Definição de exceções

Criado com o objetivo de reduzir as inconsistências no final das rotinas de apuração e fechamento de custos e identificar contradições no decorrer do período.

– Cria regras dinâmicas de validação

– Apresenta o detalhamento de ajustes em rotinas que são executadas

– Possibilidade de criar telas customizadas conforme regras do processo

Apuração das taxas estruturadas por empresa e filial, e:

– Por setor

– Por centros de trabalho

– Por categoria dos processos

– Gráficos de evolução por setor

– Com opção de evolução mensal

– Por ordem de produção

– Custos totais (processo, materiais, O.P)

– Custo de produção (total, unitário, centro de trabalho)

– Consumo de materiais (total e unitário)

Análise de rentabilidade e margem por: Empresa, Filial e Período.

Apresenta análises de rentabilidade por: Cliente, Produto, Grupo de Produtos, Vendedor e Comparativo de resultado (CPV e Lucro) entre o Custo Padrão e o Custo Real.

Entre em contato com o nosso time de especialistas e entenda como nossa plataforma pode auxiliar sua empresa.